Onsite Forklift Training

Build real skills, gain your licence, and train safely with Australian Forklift Training — SafeWork NSW approved and trusted by hundreds of Sydney worksites.

Get your forklift licence fast with Australian Forklift Training (RTO ID: 91037). Since 2001, we’ve trained over 20,000 students across Sydney. Whether you need an Express, Standard, or Premium course, we’ll help you become job-ready in days.

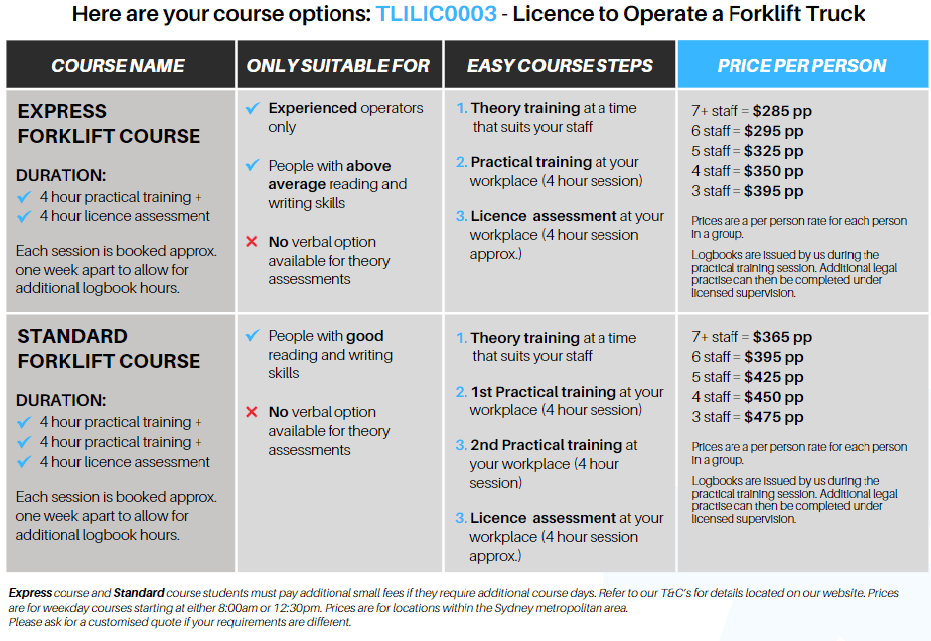

Compare Our Forklift Training Packages

Nearly 35% of warehouse injuries involve forklifts, making proper operator onsite forklift training essential for workplace safety and regulatory compliance. While traditional training programs require employees to travel to external training facilities, onsite forklift training brings certified instructors and equipment directly to your workplace. Conducting onsite forklift training can help ensure that all operators are licensed in a timely manner, which reduces the risk of accidents.

Ready to Fast-Track Your Team's Forklift Certification?

Do you have a workforce eager to attain forklift certification swiftly? In today’s fast-paced world, time is precious, and we respect that. This is why we are here to provide you with the latest insights and guidance on expediting your forklift certification through on-site training.

The Essentials of Forklift Training

Before we delve into the details, let’s lay the groundwork by briefly discussing the core components of forklift training: theory, practical training, and assessment. These fundamental elements ensure a comprehensive grasp of forklift operation and skill development, setting the stage for success in the workplace.

Theory: TLILIC0003 Forklift License Course

The TLILIC0003 Licence to operate a forklift truck, commonly known as the forklift license course, delves into the indispensable theoretical knowledge necessary for the secure and efficient operation of a standard counterbalance forklift truck. This foundation is crucial for aspiring forklift operators as it provides insights into forklift safety, operation, and ultimately, obtaining a forklift license and a high-risk work license.

Topics covered include pre-operational checks, load handling, and workplace safety.

Practical Training: Counterbalance Forklift & High Reach Forklift

With the theoretical groundwork laid, it’s time to get hands-on with real-world practical training. Counterbalance forklift training equips you with the skills and knowledge to operate a standard counterbalance forklift truck safely and efficiently. This hands-on training covers various aspects of forklift operation, including load handling, safety protocols, and maintenance.

High-reach forklift training is centered on the operation of high-reach machines designed for accessing high racks. While most courses do not include high-reach machines unless specified, this skill is essential for operators working with these specialised machines. Proficiency in both counterbalance and high-reach forklifts positions you well for a variety of roles in the field.

Assessing Your Skills: Practical and Written Examinations

We want to ensure that you’re more than prepared to embark on your forklift journey. The assessment process includes two crucial components: practical and written examinations. Let’s break it down for you.

During the practical examination, our assessors will evaluate your ability to perform safety checks, navigate obstacles, and handle various loads. We want to make sure you can safely maneuver a forklift in real-world scenarios.

As for the written examination, it tests your understanding of forklift operation, safety regulations, and load handling. By acing both of these exams, you’ll be well on your way to securing your forklift certification.

Why Choose Registered Training Organisation (RTOs)

If you’re seeking top-tier forklift training, look no further than a registered training organisation. Organisation like Australian Forklift Training offer accredited courses guided by experienced trainers to ensure your forklift training is of the highest quality.

RTOs are approved by the Australian Skills Quality Authority (ASQA) to provide nationally recognized training in the vocational education and training (VET) sector. This means your training is not only comprehensive but also respected across the industry.

Certified Training Programs

Our accredited training programs adhere to strict quality standards set by the ASQA. These certifications are nationally recognized, ensuring you stand out in various industries. With accredited courses provided by RTOs, you can rest assured that you’re receiving top-notch forklift training.

Expert Instructors

The role of experienced trainers in forklift training is invaluable. These seasoned professionals bring industry experience and hold certifications such as the Certificate IV in Training and Assessment. This ensures that they can effectively deliver and assess vocational training courses.

Our experienced trainers provide expert guidance and support throughout the training process, ensuring that you acquire the essential skills and knowledge to operate forklifts safely and efficiently.

Book your forklift training at our Blacktown or Moorebank centre

Onsite Forklift Training: Complete Guide to Workplace Certification

Nearly 35% of warehouse injuries involve forklifts, making proper operator training essential for workplace safety and regulatory compliance. While traditional training programs require employees to travel to external training facilities, onsite forklift training brings certified instructors and equipment directly to your workplace. Conducting onsite training can help ensure that all operators are licensed in a timely manner, which reduces the risk of accidents.

This comprehensive guide covers everything you need to know about workplace-based forklift certification, from understanding the training requirements to choosing the right provider for your business needs.

We deliver training for the nationally recognised units:

TLILIC0003– Licence to operate a forklift truck

TLILIC0004– Licence to operate an order picking forklift truck

What is Onsite Forklift Training

Onsite forklift training is a specialised educational program delivered directly at your workplace location, where certified instructors bring their expertise and training equipment to your business premises. This approach allows employees to learn forklift operation using your actual warehouse layout, loading docks, and the specific equipment they’ll operate daily. Onsite forklift training can be delivered as a comprehensive forklift course, covering both theory and hands-on practice to ensure participants gain practical skills and meet compliance requirements.

Unlike traditional training center-based courses that require employees to travel to external facilities, onsite training courses are conducted in your familiar environment. This method ensures that practical training directly addresses the unique hazards, procedures, and operational challenges specific to your workplace. Onsite forklift training courses are designed to meet the same standards as offsite programs, ensuring participants receive practical and compliant training.

The primary qualification obtained through workplace-based assessment is the TLILIC0003 licence to operate a forklift truck. Forklift licencing is a legal requirement in Australia, and onsite training helps ensure all staff are properly licenced. This nationally recognised certification is a High Risk Work (HRW) licence requirement for forklift operation in Australia, ensuring that operators meet industry standards for safe equipment operation. Upon successful completion, participants receive a nationally recognised statement of attainment, which is accepted across Australia.

Onsite training programs typically combine theoretical instruction with hands-on practical assessment, allowing forklift operators to develop the skills required for daily operations while maintaining business continuity. Training builds operators’ confidence, leading to more efficient and motivated performance.

Benefits of Onsite Forklift Training

Choosing onsite training over traditional training centre programs offers significant advantages for businesses seeking cost effective solutions for staff development.

Operational Efficiency

The most immediate benefit is reduced operational downtime, as staff can train during regular work hours without disrupting production schedules. This flexible scheduling approach means experienced operators can continue their routine checks and essential tasks while new employees receive comprehensive training. Onsite forklift training minimises downtime for businesses while maximizing learning efficiency, ensuring that training sessions are both effective and convenient. Proper operation helps prevent costly damage to forklifts, reducing repair costs and downtime.

Cost Savings

Businesses achieve substantial cost savings by eliminating travel expenses, venue hire fees, and additional accommodation costs for regional employees. However, businesses should inquire about any potential additional fees, such as location surcharges or regulatory compliance costs, to ensure transparency and avoid unexpected expenses. When training multiple staff members simultaneously in group sessions, the per-person cost decreases significantly compared to individual offsite training programs.

Workplace-Specific Training

Training on actual workplace equipment in your familiar environment ensures that practical skills directly transfer to daily operations. Instructors can address specific workplace hazards unique to your site, incorporating your loading dock configurations, storage systems, and internal safety procedures into the training program.

Real-World Application

Onsite forklift training allows participants to practice real-world scenarios using company infrastructure. This includes navigating actual aisle widths, working with existing storage heights, and understanding the specific challenges of your warehouse layout that wouldn’t be replicated in a generic training facility.

Training Requirements and Eligibility

Before enrolling in any forklift training course, participants must meet specific eligibility criteria to ensure they can safely operate heavy machinery in workplace environments.

Age and Documentation Requirements

The minimum age requirement is 18 years for forklift licence applications in Australia. Participants must provide valid photo identification such as a current driver’s licence or passport to verify their identity and age.

Language and Literacy Skills

Basic English literacy is essential to understand safety instructions, regulations, and operational procedures. This requirement ensures that operators can comprehend written safety procedures, warning signs, and emergency protocols essential for safe operation.

Medical and Physical Requirements

Participants must complete a medical fitness declaration confirming their ability to operate heavy machinery safely. This includes declaring any medical conditions that might affect their capacity to operate equipment or respond to emergency situations.

Personal Protective Equipment

All participants must have appropriate personal protective equipment before commencing training sessions. This includes hi-vis clothing, steel-capped boots, and any additional safety equipment specified by workplace safety regulations or site-specific requirements.

Work Health and Safety

At Australian Forklift Training, work health and safety are at the core of every onsite training course we deliver. Our comprehensive training programs are designed to equip participants with a thorough understanding of safety procedures, safety regulations, and best practices for operating a forklift truck in any workplace. Each training session covers essential topics such as hazard identification and risk assessment, ensuring that every operator can recognise and control potential dangers before they become incidents. By integrating these critical elements into our onsite training courses, we help businesses foster a culture of safety, reduce workplace accidents, and ensure compliance with all relevant safety standards. Our commitment to work health means every participant leaves our courses with the knowledge and confidence to operate safely and responsibly, protecting themselves and their colleagues during daily forklift operations.

Course Content and Curriculum

Comprehensive training programs combine theoretical knowledge with practical skills development to ensure operators achieve competency in all aspects of forklift operations. Forklift courses are designed to ensure participants are fully prepared for workplace safety and compliance. Successfully completing these courses enables operators to obtain the necessary certification and legally operate forklifts in the workplace. The training duration for forklift certification is typically 2 to 3 days, providing ample time to cover all essential topics and practical skills.

The training duration typically spans 2-3 days for a complete certification program, ensuring participants receive thorough understanding of both technical and safety aspects. All training courses must comply with Australian Standards and workplace health and safety regulations to meet nationally recognised certification requirements.

Theoretical Components

The classroom portion covers fundamental concepts that form the foundation of safe forklift operations:

Forklift design features including stability principles, load capacity calculations, and center of gravity concepts that affect safe operation

Pre-operational inspection procedures and comprehensive safety checklists that operators must complete before each shift

Hazard identification and risk assessment techniques specific to warehouse environments and material handling operations

Legislative requirements covering operator responsibilities under Work Health and Safety laws and compliance obligations

Load handling techniques including proper lifting procedures, load positioning, and understanding weight distribution principles

Key topics of classroom training include legal requirements and company policies, anatomy and mechanics, stability principles, load handling, hazard identification, and attachments

Practical Training Elements

Hands-on training ensures operators develop the practical skills necessary for competent equipment operation:

Equipment operation covering counterbalance and reach truck forklifts, with instruction on controls, maneuvering, and proper operating techniques

Loading and unloading procedures for trucks and storage areas, including safe approach methods and positioning techniques

Maneuvering skills for operating in tight spaces and navigating around workplace obstacles while maintaining safety margins

Proper procedures for parking, refueling, and equipment shutdown following manufacturer specifications and workplace protocols

Emergency response training covering incident reporting requirements and appropriate actions during equipment malfunctions or accidents

Types of Forklift Licenses Available

Different workplace environments require specific forklift qualifications based on the equipment type and operational requirements.

Standard Forklift Licence

The TLILIC0003 standard forklift licence covers counterbalance and reach trucks commonly used in warehouse and manufacturing environments. This licence permits operation of equipment up to 10 tonnes capacity and forms the foundation for most industrial forklift operations.

Specialised Equipment Licences

Order picker licence enables operators to use warehouse picking equipment for operations above 1.8 meters height. This specialized certification is essential for businesses with high-bay storage systems and elevated work platform requirements.

Container handler licence covers heavy-duty equipment used in shipping yards and port operations, where operators handle shipping containers and oversized loads requiring specialized handling techniques.

Rough terrain forklift licence applies to outdoor construction sites and uneven surfaces where standard warehouse equipment isn’t suitable for the operating conditions.

Refresher Training

Existing licence holders must complete refresher training every 2 years to maintain their certification. Refresher courses update operators on regulation changes, reinforce safety procedures, and assess continued competency in equipment operation. Additionally, the forklift licence must be renewed every 5 years to ensure operators remain compliant with legal and safety standards. Refresher training for operators is typically required every three years and mandatory retraining is required after an accident, near-miss, unsafe operation, or if assigned to a new type of forklift.

Training Duration and Scheduling

Flexible scheduling options accommodate different business needs and operational requirements while ensuring comprehensive skill development.

Standard Training Programs

The standard 2-day program provides 8 hours total training time, combining theoretical instruction with sufficient practical training to achieve competency. This duration allows thorough coverage of all curriculum elements while providing adequate practice time for skill development.

Accelerated Options

Fast-track 1-day courses are available for experienced operators who need formal certification but already possess practical skills. These intensive sessions focus on assessment and certification while covering any knowledge gaps in formal procedures or regulatory requirements.

Flexible Arrangements

Training providers offer flexible scheduling including weekends and after-hours sessions to minimize disruption to business operations. Part-time options allow training spread over multiple weeks, accommodating shift workers and businesses with limited staff availability.

Group Training Benefits

Group bookings for 3-8 participants provide discounted rates while enabling multiple staff members to achieve certification simultaneously. This approach is particularly cost effective for businesses expanding their workforce or implementing new safety protocols.

Assessment and Certification Process

The certification process combines written assessment with practical demonstration to ensure operators achieve competency before receiving their licence.

Written Theory Assessment

Participants complete a written theory assessment covering safety regulations, operational procedures, and legislative requirements. This assessment verifies understanding of theoretical concepts essential for safe equipment operation.

Practical Driving Test

The practical assessment demonstrates competent forklift operation under realistic workplace conditions. Experienced trainers evaluate participants’ ability to safely operate equipment, perform pre-operational checks, and respond appropriately to common workplace scenarios.

Certification Timeline

Upon successful completion of both assessments, participants receive an immediate temporary licence enabling workplace operation while permanent documentation is processed. The Statement of Attainment is provided within 30 days of assessment completion. Individuals can attain a temporary WorkSafe forklift licence after course completion, allowing them to begin operating forklifts while awaiting their permanent certification.

Licence Processing

High Risk Work licence applications are submitted to SafeWork authorities as part of the certification process. Participants receive a 60-day temporary permit allowing immediate workplace operation while permanent licence cards are issued.

Training Locations

Australian Forklift training offers flexible onsite training courses throughout Sydney and the surrounding areas, making forklift licence training accessible and convenient for businesses of all sizes. Whether you prefer to train at our fully equipped training facility or opt for on site forklift training at your own workplace, we provide tailored training programs to suit your needs. Our trainers bring the forklift training course directly to your site, allowing participants to learn in a familiar environment and practice on the actual equipment they will operate daily. This approach not only enhances learning outcomes but also ensures that licence testing and practical assessments are relevant to your specific workplace conditions. No matter where you are located in Sydney or nearby suburbs, Australian Forklift Training is ready to deliver high-quality training courses and help your team achieve their forklift licence efficiently and effectively.

Choosing the Right Training Provider

Selecting an appropriate training provider ensures quality instruction and compliance with all regulatory requirements.

Accreditation Verification

Verify that providers maintain current RTO (Registered Training Organisation) registration and SafeWork accreditation status. These credentials ensure training meets national standards and qualifications are recognised across Australia.

Trainer Qualifications

Confirm that instructors hold appropriate qualifications including TAE40116 training credentials and current forklift operation experience. Qualified trainers provide quality instruction while understanding both theoretical concepts and practical application.

Insurance and Safety

Ensure providers maintain comprehensive insurance coverage for onsite training activities and equipment. This protection covers potential accidents or equipment damage during training sessions conducted at your workplace.

Industry Experience

Choose providers with demonstrated experience in your specific warehouse or manufacturing sector. Industry-specific knowledge ensures training addresses relevant hazards and operational challenges unique to your business environment.

Provider Reputation

Review customer testimonials and safety records of potential training organizations. A great teacher with proven results and positive feedback indicates quality instruction and successful outcomes for previous participants.

Commitment to Quality

At Australian Forklift Training, our commitment to quality is reflected in every aspect of our forklift training programs. We adhere to the highest industry standards and safety regulations, ensuring that each forklift training course is both comprehensive and up-to-date. Our experienced trainers are dedicated to delivering engaging, practical assessments and providing ongoing support throughout the training process. We focus on helping every participant successfully complete their course and obtain their forklift licence, recognising that a well-trained workforce is essential for maintaining a safe and productive workplace. By prioritising participant satisfaction and continuous improvement, we strive to be the trusted choice for businesses seeking reliable, high-quality forklift training that meets all regulatory and industry requirements.

Cost Considerations

Understanding the investment required for onsite forklift training helps businesses budget effectively while maximising training value.

Individual Training Costs

Individual training costs typically range from $350-$550 per participant, depending on location, course duration, and specific requirements. This investment covers comprehensive training, assessment, and initial certification documentation.

Group Discounts

Significant savings are available through group discounts for 3+ participants, with per-person fees reducing substantially for larger groups. These discounts make onsite training particularly cost effective for businesses training multiple employees simultaneously.

Additional Considerations

Regional surcharges may apply for locations outside major cities, reflecting travel costs for instructors and equipment transport. For example, surcharges may apply for training delivered in areas such as the Illawarra or Central Coast, due to additional travel and accommodation costs. Package deals combining forklift and order picker certifications offer enhanced value for businesses requiring multiple licence types.

Payment Options

Most training providers offer flexible payment options including corporate invoicing for training programs. This flexibility accommodates different budgeting cycles and procurement processes while ensuring staff can commence training without delays.

Cost Comparison Benefits

When comparing costs, consider the comprehensive savings of onsite training versus offsite alternatives. Beyond direct training fees, onsite programs eliminate travel expenses, accommodation costs, and productivity losses associated with staff absence from the workplace.

The investment in quality onsite forklift training delivers long-term value through improved safety outcomes, regulatory compliance, and enhanced operational efficiency. With proper training, businesses reduce accident risks, minimize equipment damage, and ensure their workforce operates equipment safely and competently. Forklift training helps increase employment opportunities and earning potential for individuals.

By choosing onsite training that meets your specific operational needs, you’re investing in a comprehensive solution that delivers immediate certification while building lasting safety culture within your organization.

How to Enroll

Enrolling in one of our forklift training courses is simple and convenient. Visit our website to access the registration form, where you can provide your details and select your preferred training program. We offer flexible scheduling options to accommodate your business needs and individual commitments, ensuring that training sessions fit seamlessly into your workflow. Our training programs can be tailored to address the specific requirements of your workplace, providing a personalized learning experience. Upon successful completion of the forklift training course, participants receive a nationally recognised certification and become eligible to apply for a high risk work licence. If you have any questions or need assistance during the enrollment process, our friendly team is always available to help guide you every step of the way.

Ongoing Support

At Australian Forklift Training we understand that maintaining forklift skills and knowledge is just as important as initial training. That’s why we offer ongoing support through refresher courses and advanced training programs, designed to help experienced operators stay up-to-date with the latest industry standards and safety regulations. Effective training extends beyond initial certification and includes a commitment to ongoing education and safety culture. Corporate training can include refresher courses to ensure ongoing employee competency. Our team is committed to providing comprehensive training and expert guidance, ensuring that all participants continue to operate safely and efficiently long after completing their forklift training course. Whether you need to refresh your skills, update your certification, or seek advice on best practices, AFT is here to support your ongoing development and help you maintain a safe, compliant, and productive workplace.

Quick links to resources:

- Many students ask, can you fail a forklift licence test — we explain what to expect.

- New to VOC? Here’s what a forklift Verification of Competency really means

- Brush up on forklift safety mistakes you should avoid to stay compliant

- What is a Forklift VOC (Verification of Competency)? → “Book your forklift VOC assessment

- Can You Fail a Forklift Licence? → “Stay current with a VOC verification